Bending Includes Which of the Following Principle Types of Stress

54 Normal Stress in Beams Linear Elastic Materials x occurs due to bending the longitudinal line of the beam is subjected only to tension or compression if the material is linear elastic then x E x - E y vary linear with distance y from the neutral surface consider a positive bending moment M applied stresses are. For bending analysis of isotropic circular plate.

Workflow For Cnc Machining Cnc Machine Cnc Mechanical Design

Stress varies linearly over cross section.

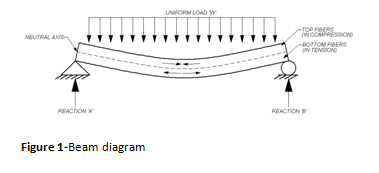

. The bottom fibers are in compression and the top fibers are in tension. Thus the stress is negative and the shear stress on the right edge is drawn in the up direction. The bending or static analysis of thin circular plate includes the use of cylindrical coordinate system in which normal and shear stresses are functions of two coordinates viz.

Under combination of these stresses d Principle Stress. For internal equilibrium to be maintained the bending moment will be equal to the M from the normal stresses the areas the moment arms. Analytical results obtained from CPT are validated with the results of ANSYS software.

The stresses included are those due to tension bending shear and hoop stress. Assume the load w o to be increasing progressively until the beam fails. In upset forging the aspect ratio length to diameter ratio should be 31.

Superposition - Add the stresses together into a Stress Tensor. The beam will go into the following three stages. Buckling is characterized by a sudden sideways failure of a structural member subjected to high compressive stress where the compressive stress at the point of failure is less than the ultimate compressive stress that the material is capable of withstanding.

Also important is the size of the bend bend radius angle of bend curvature of bend and location of bend in the work piece. The maximum shear stress is. Highly efficient complex types of machinery are used for hot bending.

The factors or bending equation terms as implemented in the derivation of bending equation are as follows M Bending moment. Where Nx NO and Nx0 are the membrane stress resultants Mx and Mx0 are the bending stress O O O resultants ex e_ and _x0 are the middle-surface membrane strains and Kx and Kx0 are the middle- surface bending strains. Induction Bending Hot Bending.

We call this kind of bounce as bending spring back. To calculate the level of stress on a structure strain is measured. The hot bending Process is efficient for larger pipe diameters.

Torsional Moment τ σ Bending Moments z x y MT y Mx or Torque Force Components Moment Components Cut Surface Cut Surface Centroid of Cross Section Centroid of Cross Section Normal Force. Bending processes differ in the methods they use to plastically deform the sheet or plate. You can view uniform axial stresses torsional bending and shear stresses in two orthogonal directions dir 1 and dir 2 and the highest stresses on extreme fibers generated by combining axial and bending stresses.

σ Stress of the fibre at a distance y from neutralcentroidal axis. The shear stress is acting down on the right edge of the stress element. 2 The shear stress ratio for the ultimate condition is customarily expressed as u su su f R F 6 where su is the ultimate shear stress allowableF 2.

Fast Process as no heating cooling involved. Calculating Bending Stress using SkyCiv Beam. If the beam is sagging like a U then the top fibers are in compression negative stress while the bottom fibers are in tension positive stress.

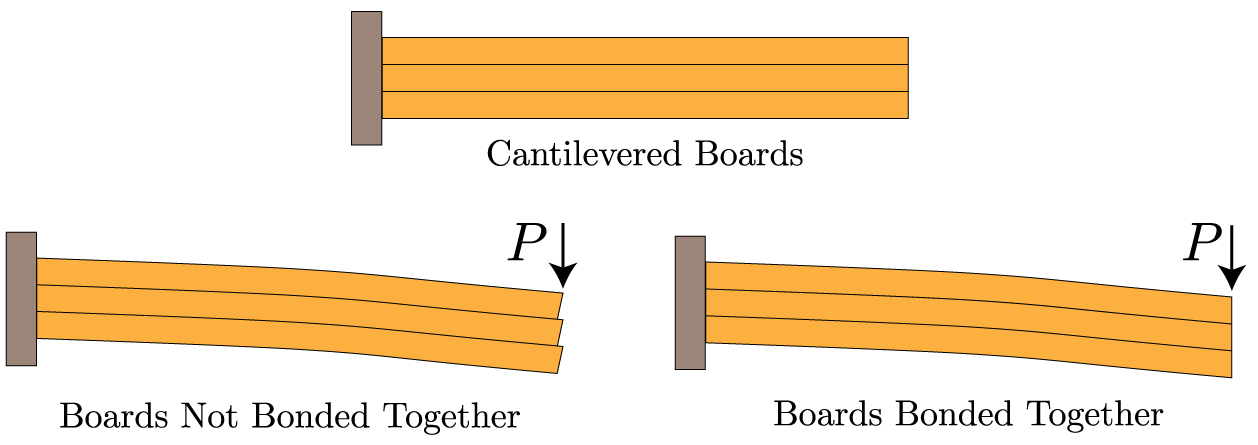

Although normal bending stresses appear to be of greatest concern for beams in bending shear stresses do exist in beams when loads ie transverse loads other than pure bending moments are applied. The so-called bending is the deformation of tensile stress and compressive stress on the front and back of the same plate. E Youngs Modulus of beam material.

Geometric fit helps solve this statically indeterminate problem. Uncrack Concrete Stage at this stage the gross section of the concrete will resist the bending which means that the beam will behave like a solid beam made entirely of concrete. C Torsional Stress shear where T torque r radius of shaft J polar moment of inertia Combined Stresses.

Transverse Shear Stress Normal Bending Stress Torsional Shear Stress pressure Vessel Stresses 6. There is no normal vertical stress so σ y is zero. The case of a centrally-located hole is present during pure bending in Fig.

The bending stress is considered to be acting in the x direction. I The moment of inertia ii The radius of curvature is iii The maximum bending stress is iv The bending stress at the point 08 cm from the neutral axis is arrow_forward A beam has a bending moment of 35 kN-m applied to a section with a hollow circular cross-section of the external diameter of 36 cm and an internal diameter of 2 cm. R Curvature radius of this bent beam.

Heat Input is a must in induction or hot bending. In comparison to measure the normal strains on the surface of a body it is quite. A Direct stress where P axial thrust A area of cross-section b Bending stress where M bending moment y- distance of fibre from neutral axis I moment of inertia.

311 Principles of the structural stress or strain approach. The stress in magnitude and direction acting on a body can be determined by using the measured strain and certain properties of material like Modulus of Elasticity and Poissons Ratio. Axial Force z x y P Centroid σ Axial Stress Cut Surfaceσ P A l Uniform over the entire cross section.

I Moment of inertia exerted on the bending axis. If the beam is sagging like an upside-down U then it is the other way around. Work piece material size and thickness are important factors when deciding on a type of metal bending process.

The normal planes remain normal for pure bending. Up to 24 cash back Stress concentrations Bending Discontinuities such as holes and notches cause regions of increased stress during bending in much the same way as tension. This clearly defined structural stress for plate-type structures can only be.

Scaling is done either by the stress loading factors or will be done automatically if homogeneous pipe additional bending stiffness is in use. The dashed line represents the nominal stress that would be present in the absence of the hole. Consider a relatively long simply supported beam shown below.

The loads tension bend moment shear and torque which are used in stress calculations are scaled before being used. The stress at the surface after a stress linearization in the thickness direction. The structural stress can also be regarded as the sum of the axial and bending stress in a plate or shell ie.

L Axial force must go through centroid. There is no net internal axial force. When a stress state involves shear the following shear stress ratio for the yield condition is customarily expressed as y sy sy f R F 5 where sy is the yield F shear stress allowable.

Once the plate is bent to the target angle the material will bounce back to its original shape once the pressure is removed due to tensile stress and compressive stress. Draw the stress distribution diagrams and determine the stress magnitude and direction.

Bending Stress An Overview Sciencedirect Topics

The Formula For Bending Stress Strucalc By Vitruvius

Pin By Peter Holubowski On Concours D Architecture In This Moment Civil Engineering Construction Compressive Strength

It S Safe To Say That All Bodies Are Made In A Different Way So Perhaps Despite Hearing How Terrific Cardio Is Fo Chair Yoga Yoga For Seniors Chair Pose Yoga

Elements Of Bend Metal Bending Metal Bending Tools Bend

Bbs Bar Bending Schedule For Beam Bbs For Beam Lceted Part 1 Civil Engineering Design Beams How To Make A Bar

Mechanics Of Materials Bending Shear Stress Mechanics Of Slender Structures Boston University

Combined Stresses Axial Bending Stresses Youtube

Types Of Stress In Strength Of Materials Understanding Business Analysis And Engineering Principles

Pin On Mechanical Information S Source

Types Of Stresses Tensile Compressive Shear Torsional Beding Stress Youtube

Comments

Post a Comment